HMT Products

About HMT

Johsun Seal Servicing WA Ltd is currently in partnership with a major World Leading Company, HMT LLC. HMT is the global leader in aboveground storage tank solutions. HMT provides advanced solutions to reduce emissions, optimize tank capacity, reduce stranded inventory and engineer a tank system that exceeds safety standards and extends maintenance intervals.

Products

- External Floating Roof Seals – Primary Seals

- Internal Floating Roof Seals – Primary Seals

- MINI-SHOE™ Primary Seal for Aluminum IFRs

- MINI-SHOE™ Primary Seal for Steel IFRs

- Retro-Fit Primary Seal

- Scissor Shoe Primary Seal

- Seal Master™ Primary Seal

- Internal Floating Roof Seals – Secondary Seals

- Seal Master™ Secondary Seal

- VAPORFLEX™ Secondary Seal

- SEAL KING™ Secondary Seal Internal Floating Roofs

- Skin & Pontoon Internal Floating Roofs

- UNIDECK® Aluminum IFR

- UNIDECK® Stainless Steel IFR

- ALUMINATOR® 1000 Aluminum IFR

- ALUMINATOR® 1000 Hybrid IFR

- Full Contact Internal Floating Roofs

- ALUMINATOR® HFCIFR

- Deck Master Advanced Composite IFR Aluminum Domes

- Aluminum Domes for Aboveground Storage

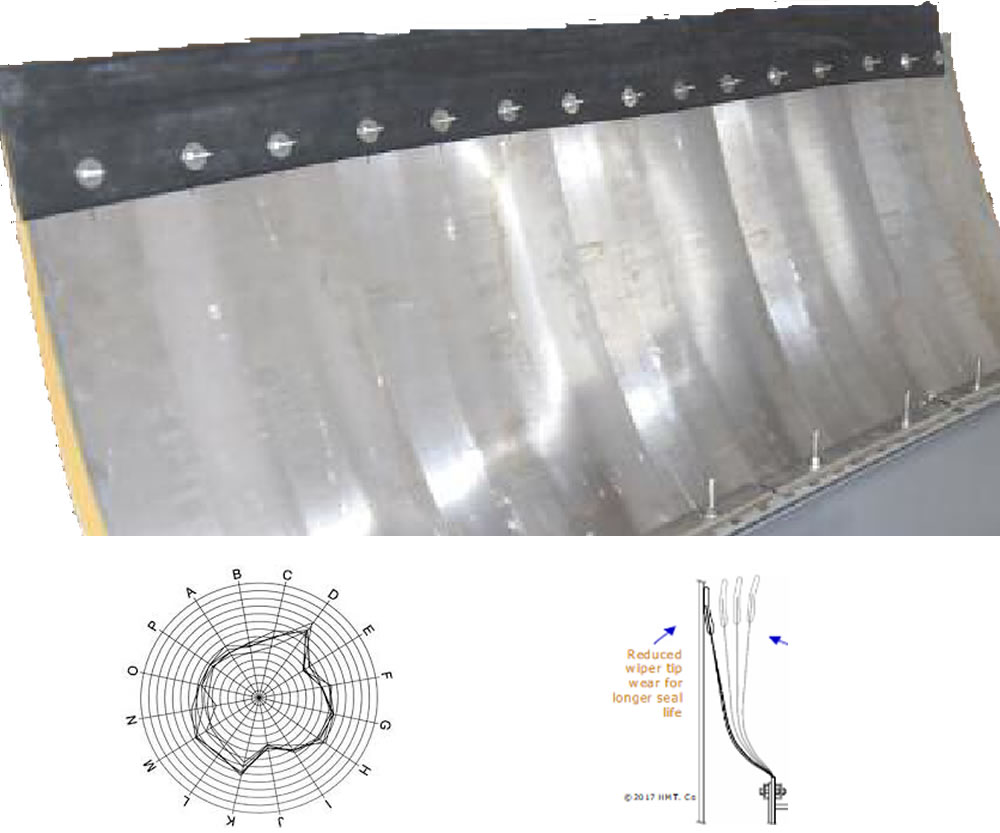

FLEX-A-SEAL TM SECONDARY SEAL

The HMT FLEX-A-SEALTM Secondary Seal is one of the most economical and effective types of secondary seals available. Easily installed and maintained, the HMT FLEX-A-SEAL’s ability to meet or exceed stringent gap specifications for secondary seals has earned its approval from governmental regulatory agencies throughout the U.S. and European markets.

For a secondary seal that is custom designed to fit specific tank round anomalies, has exceptional gap sealing ability, allows for in-service installation and has a long service life, choose the FLEX-A-SEALTM Secondary Seal.

The FLEX-A-SEALTM Secondary Seal’s advanced design features include:

No gapping — engineered to ensure tension will hold up year after year and seals won’t gap, maintaining a tight seal

Long life — engineered to ensure spring longevity and long-lasting seal performance

Maintenance-free operation — work horse design and materials

In-service install — no hot work required

Custom designed — each tank has its own variations in roundness and verticality; HMT custom designs every seal to ensure an excellent fit with no gaps

• Continuous fabric vapor barrier under plates

• Premium fabrics for long-life and durability

of vapor barrier

• Bolt-on design allows for in-service

installation

• Compression plates not bolted together

allowing to move and flex, taking shape of

the tank shell

• Compression plates available in variou s

widths allow for improved sealing to all tank

radii

• Completely bolted assembly eliminates all

rivets which allows for easier and safer tank

maintenance

• Protector clips to encapsulate metallic bolt

head, increasing safety

• Tip profile options to counter large welds or

tank shell deformities

1. Continuous compression-plate and fabric system

The FLEX-A-SEAL TM utilizes a system of overlapping steel plates which provide the pressure to maintain zero gap. The FLEX-A-SEAL TM does not rely on gas-kets between these plates (which can quickly wear out and fail) ; instead, the vapor barrier is provided by a continuous fabric underneath the plates.

2. Each seal tailored to the tank

Each tank has its own variations in roundness and verticality. To ensure a zero-gap fit, each FLEX-A-SEAL TM Seal is custom-designed . We don’t use one size-fits-all parts. Varying length plates may be used for varying rim spaces within a given tank.

3. Handles a wide range of products and service conditions

A highly effective seal due to its wide range of vapor barrier fabrics, combined with a Buna/Nitrile PVC blend tip. Designed to be installed with the tank in service and engineered to adapt to virtually every type of external floating roof design. Accommodates wide variations in annular rim space and is compatible with various types of primary seals and rim connections. The FLEX-A-SEAL TM combines economy with durability.

Custom-hardened stainless steel

A significant benefit to HMT’s custom-hardened steel is there is less pressure required to maintain the tip contact with the shell. This translates into

two major benefits for our customers; seal inspections are easier due to ease of pull-back when inspecting and reduced wiper tip wear which results

in a longer seal life.

Industry-leading fabrics

The other area where HMT outperforms the rest is in

the quality and durability of our fabrics. We offer a variety of fabric choices, depending on your service requirements. Our standard PT FE fabrics are laminated, which are unsurpassed in terms of durability,

impermeability and service life. HMT’s fabrics will wear extremely well in even the most aggressive services.

Other benefits and options

• Excellent water shedding capability

• HMT fabrics are conductive for static dissipation

• Available in galvanized or stainless steel

• Wide range of metallic and non-metallic materials available for various service conditions

• Foam ports available

• With use of special protector clips, seal will return to tank without special attention if tank is overfilled

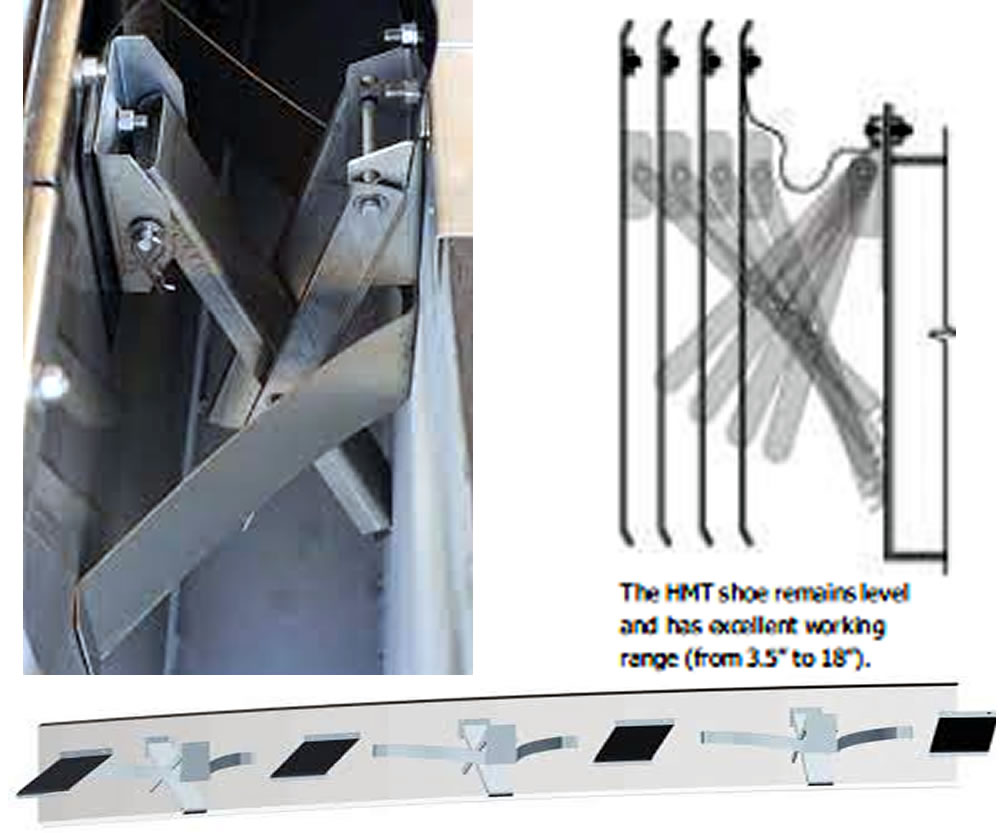

SCISSOR SHOE PRIMARY SEAL

The HMT Scissor Shoe Primary Seal for aboveground storage tanks is the primary seal of choice for external floating roofs. The original scissor shoe seal was invented by HMT in 1987, and the design has been continuously refined since then.

To this day, it remains the most widely utilized and successful primary seal in the industry. The reasons are clear: it works and it’s extremely durable.

For a primary seal that will last, perform well through heavy use, adapt to tank roundness anomalies, span a wide range of rim spaces, and most importantly, maintain tank-shell contact resulting in no gaps, choose the HMT Scissor Shoe.

The HMT Scissor Shoe Primary Seal relies on innovative design features that contribute key benefits to the end user:

Handles wide range of rim spaces — scissor hanger design performs well in rim spaces ranging from 3.5” to 18” and can be custom-designed to handle rim spaces up to 24”

No gapping — good seal even with wide-ranging rim spaces and tank roundness anomalies

Long life — key components made from custom-hardened stainless steel, ensuring spring longevity and long-lasting seal performance

Low maintenance — workhorse design and materials

In-service install — no hot work required

• Custom-hardened steel will not fatigue

•Ten pressure points per shoe create even pressure distribution across the entire shoe

• HMT’s scissor shoe stays level as the rim space varies, ensuring a tight fit as roof travels

• Premium fabrics for long-life and durability of vapor barrier

• Bolt-on design allows for installation and repair while in service

• Each HMT seal is designed and sized to fit the specific tank and floating roof dimensions

• PTFE fabrics have excellent flame retardant properties; meets DIN 22118 standard

1. Even pressure application

Each shoe is equipped with three sets of pusher bars and pusher plates, for a total of ten pressure zones.This ensures even pressure distribution and allows the shoe to conform well to local anomalies in shell roundness. In addition, the pressure is distributed vertically on the shoe, ensuring excellent contact from top to bottom. There is no better shoe pressure application in the industry.

2. Remains level as rim space varies

Another major benefit of the design is that the shoe is held at the same level regardless of local rim-space variations. This ensures no “shoe-drop” in wider rim spaces (which could lead to gapping issues at shoe joints). This feature also allows for the use of low-profile secondary seals, which can add valuable capacity.

The HMT Scissor Shoe Seal handles rim spaces from

3.5” to 18”, and can be customized to handle up to 24” rim spaces.

Custom- hardened stainless steel

A critical ingredient in all our seals is the type of stainless steel we use. This steel, purchased direct

in mill-run quantities, is custom-hardened to our specification to maximize spring pressure and longevity. While annealed or off-the-shelf “quarter-hard” steel can lose its spring, HMT components will

spring back and avoid fatigue longer than any other seal on the market. This translates directly into longer life, lower maintenance, and most importantly— no

gapping.

Industry-leading PT FE fabrics

The other area where HMT outperforms the rest is in the quality and durability of our fabrics. We offer a

variety of fabric choices, depending on your service requirements. Our standard PT FE fabrics are laminated, which are unsurpassed in terms of durability, permeability and service life. HMT’s

fabrics will wear extremely well in even the most aggressive services.

Other benefits and options

• Stainless or galvanized shoe options

• PTFE or polyurethane fabric options

• Wax scrapers available

• Bolt-on design for in-service installation and repair

• Available for internal or external floating roofs

• Compliance with federal, state & local regulations

• Compatible with welded or riveted tanks

• No coil springs or under-roof counterweights

• Available with secondary seal systems

• Retrof it options available

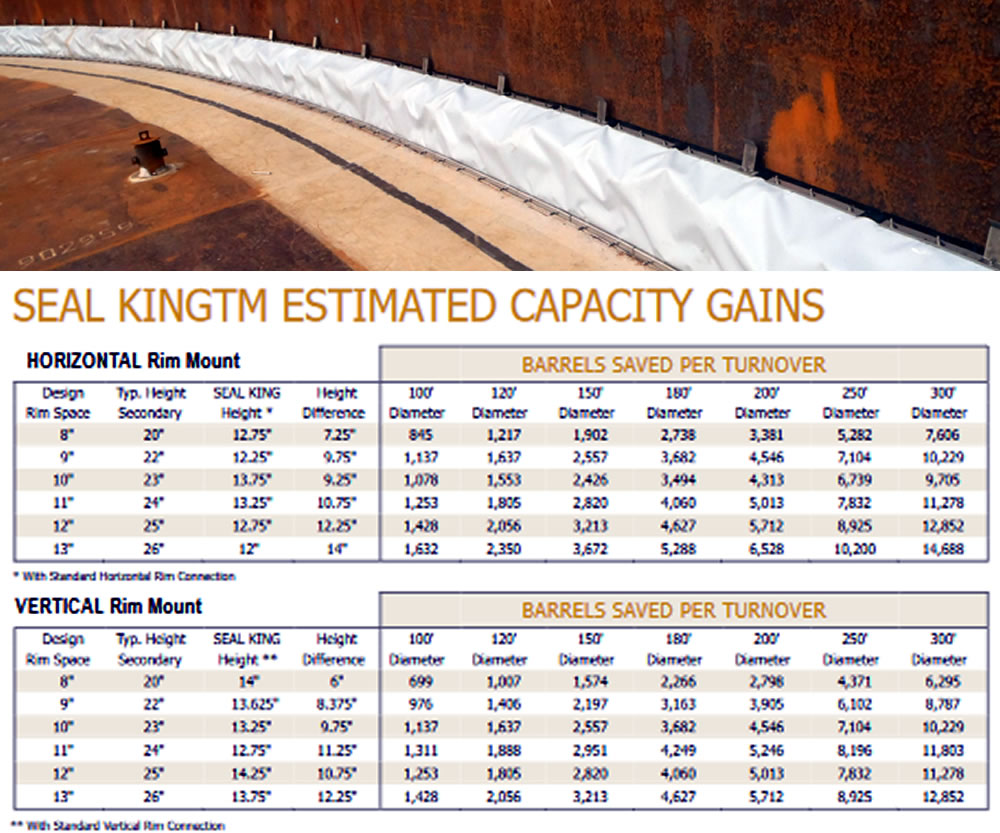

SEAL KINGTM SECONDARY SEAL

The SEAL KINGTM low-profile secondary seal was specifically designed to give storage tank owners the ability to maximize tank working capacity. With its extremely low profile, the SEAL KINGTM increases the working capacity of a floating roof tank, allowing tank owners to increase competitiveness and profitability. The SEAL KINGTM secondary seal has unsurpassed vapor sealing ability and exceptional water shedding capability

The SEAL KINGTM secondary seal increases working

capacity without sacrificing on functionality or durability. Here’s how:

Low Profile — increases storage tank capacity by increasing the maximum roof height

No gapping — engineered with custom–hardened stainless steel support arms which maintain constant continuous sealing pressure

on the tank shell

Long life — key components made from custom-hardened stainless steel, ensuring spring longevity and long-lasting seal performance

Maintenance-free operation — straight forward design, no complicated components to adjust

Easy fabric inspection — fabric on the outside for easy visual inspection

• Excellent water shedding ability

• Abrasion-resistant wiper tip

• Excellent flexibility, molds well to shell irregularities

• Low-profile design also allows shorter (and more economical) foam dam

• Premium fabrics for long-life and durability of vapor barrier

• Pre-punched fabric allows for rapid installation

• Materials are compatible with products normally stored in floating roof tanks

Quality Materials and Construction

The SEAL KINGTM low -profile secondary seal utilizes a 18-mil cross-hatched PTFE wiper tip for abrasion-resistance and maximum durability. We offer a variety of fabric choices for the vapor barrier, depending on your service requirements. Our fabrics are unsurpassed in terms of durability, permeability and service life. HDPE fabric-support straps support the SEAL KINGTM’s vapor barrier, maintaining excellent water-shedding capability.

All materials are compatible with any product normally stored in floating roof tanks, including benzene, naphtha, methanol, toluene, ETBE, TAME and MTBE. The SEAL KINGTM’s advanced materials provide exceptional service life.

The SEAL KINGTM is designed for excellent range through the use of stainless steel support arms which maintain constant and con tinuous sealing pressure and retain excellent long -term spring properties so the seal won’t gap, regardless of variations in rim space and imperfections of the shell.

LEG MASTER

Various regulatory agencies recommend that appurtenancies such as floating roof legs and leg sleeves be equipped with emission control devices. The HMT Leg Mastor or Leg Sock reduce hydrocarbon emissions from the leg and leg sleeves and these were designed under the guidance of the strictest of environment regulations.

To eliminate emissions from tank legs and leg sleeves, choose the HMT Leg Master or Leg Sock

Fast, easy install — Quickly and easily installed, and in certain cases, while the tank is in service

Quick Delivery — Delivered within two weeks of order receipt

Designed with even the strictest environment regulations in mind.

Long service life — Premium materials for the harshest environment

• Material is based for the toughest situation; a specially formulated EDPM

• The material is impervious to weather aging, stored products, ozone and ultraviolet exposure

• EDPMs dynamic and mechanical properties are excellent

• Supplied in different dimensions to fit most of floating roof legs and sleeves

LEG SOCK

Fast, easy install — Quickly and easily installed, and in certain cases, while the tank is in service

Quick Delivery — Delivered within two weeks of order receipt

Designed with even the strictest environment regulations in mind.

Long service life — Premium materials for the harshest environment

• Fabric choices depending on needs and environment, specially formulates Urethan fabric with UV protective coating or PTFE (Teflon)

• Fabric is impervious to weather, stored products and ultraviolet rays

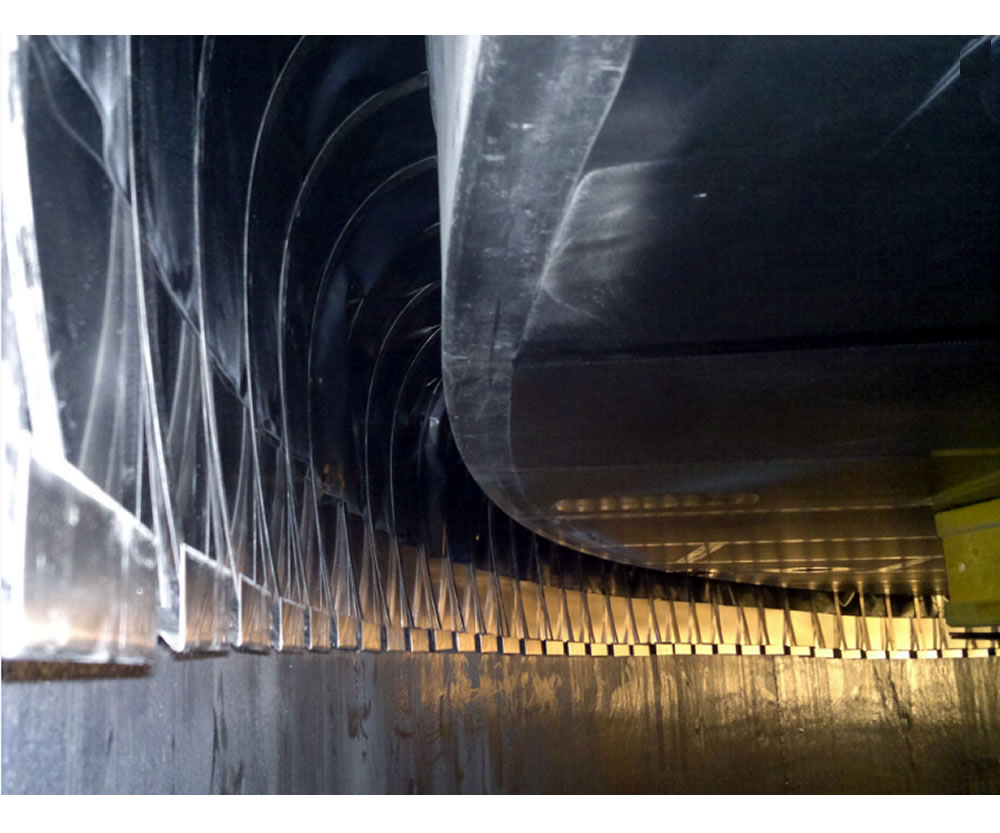

SEALMASTER PRIMARY & SECONDARY FLOATING ROOF SEAL SYSTEMS

The SealMasterTM floating roof seal system was developed over 25 years ago with the goal of making a seal that adjusts to the irregularities of tanks while remaining gas tight and virtually maintenance free. The solution is the SealMasterTM seal system.

Best available technology for emissions and product loss reduction — designed with guidance from EEMUA 159, standard working range of R(-X/+3X), highest BREF scoring and best Kra loss factor per EPA chapter 42

Designed to remain in contact with the tank at all times, regardless of structural or environmental changes — the R(-X/+3X) design

working range feature is an HMT innovation.

Under all circumstances the SealMasterTM rim seal will stay in contact with the tank shell

Flame Retardant — flame retardant membranes under guidance from DIN 22100/22188

Complete product compatibility — all construction materials are selected to be compatible with the stored product

Worry -free operation — centers the floating roof and dampens horizontal roof movement so the floating roof will not be blocked and the rim seal does not get squeezed in between the floating roof and the tank shell

• Materials are product and UV resistant

• Sliding parts in contact with the tank shell are wear resistant

• Centers the floating roof

• Effectively dampens horizontal movement of

the floating roof

• Has an adequate working range to handle all

potential tank irregularities R ( -X/+3X)

• Flame retardant

• Prevents ingress of rain water

• Secondary seal has a very low profile, allowing more filling capacity

• Gas-tight certification available

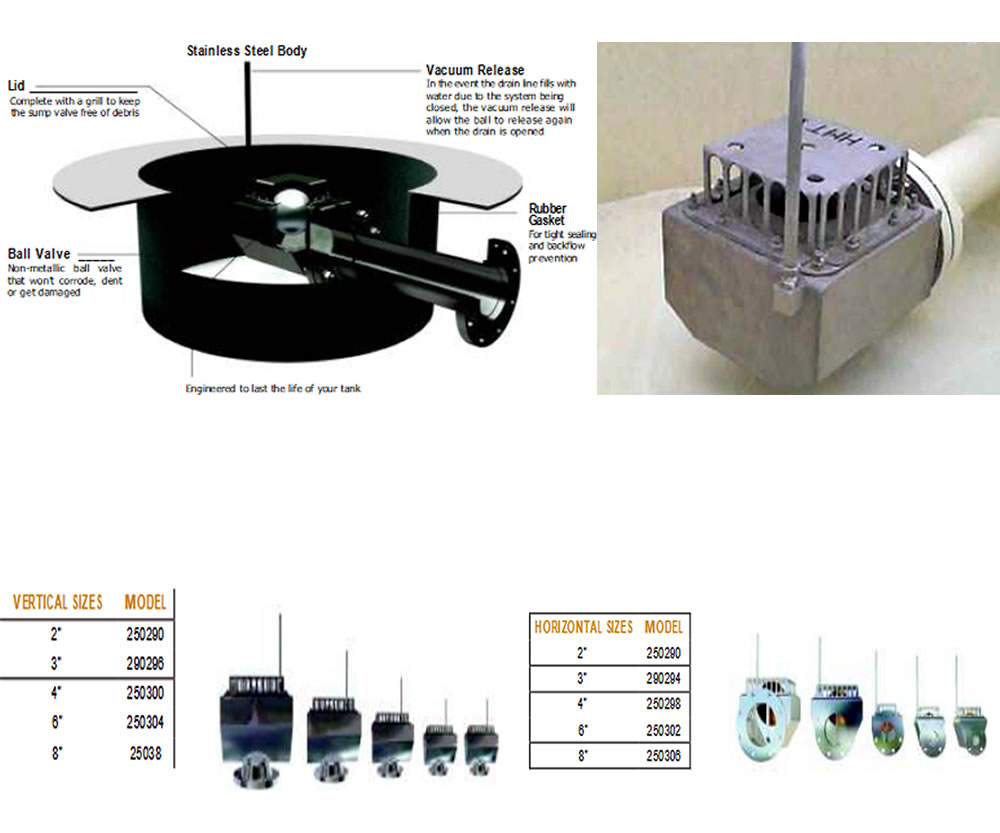

SUMPMASTER® SUMP VALVES

The SumpMaster ® is a sturdy sump valve designed to prevent product flow onto external floating roofs from drain system failures. The SumpMaster® addresses several problems with traditional check valves, including more effective sealing at the potentially lower pressures encountered during a drain system failure, and not restricting drain flow rates calculated during the design of the floating roof.

Backflow protection and peace of mind —

the SumpMaster ® keeps your roof protected from product backflow in the event of drain system failure

Maintenance -free — corrosion resistant, stainless steel construction

Superior sealing capability — in the event of product backflow, the SumpMaster ® will seal more effectively than traditional systems. Over time, metallic -ball systems develop dents from normal movement, resulting in an uneven sealing surface. The non-metallic ball of the SumpMaster® will not wear or dent, maintaining excellent sealing capabilities for the life of the tank

Fast and easy installation — easy bolt on/bolt off flanges

Custom designed — SumpMaster ® can be fit with the customer’s choice of flanges

• Designed to operate effectively at very low backflow pressures as opposed to the higher pressures required by traditional check valves

• Vacuum release allows the check ball to release in the event rainwater backs up inside the sump. When the drain line is opened from below, the ball is allowed to fall and the roof allowed to drain

• Non-metallic ball for superior wear and corrosion resistance

• Stainless steel body for superior wear and corrosion resistance

• A unique steel cage keeps the SumpMaster® free of debris

• Can be vertical or horizontal

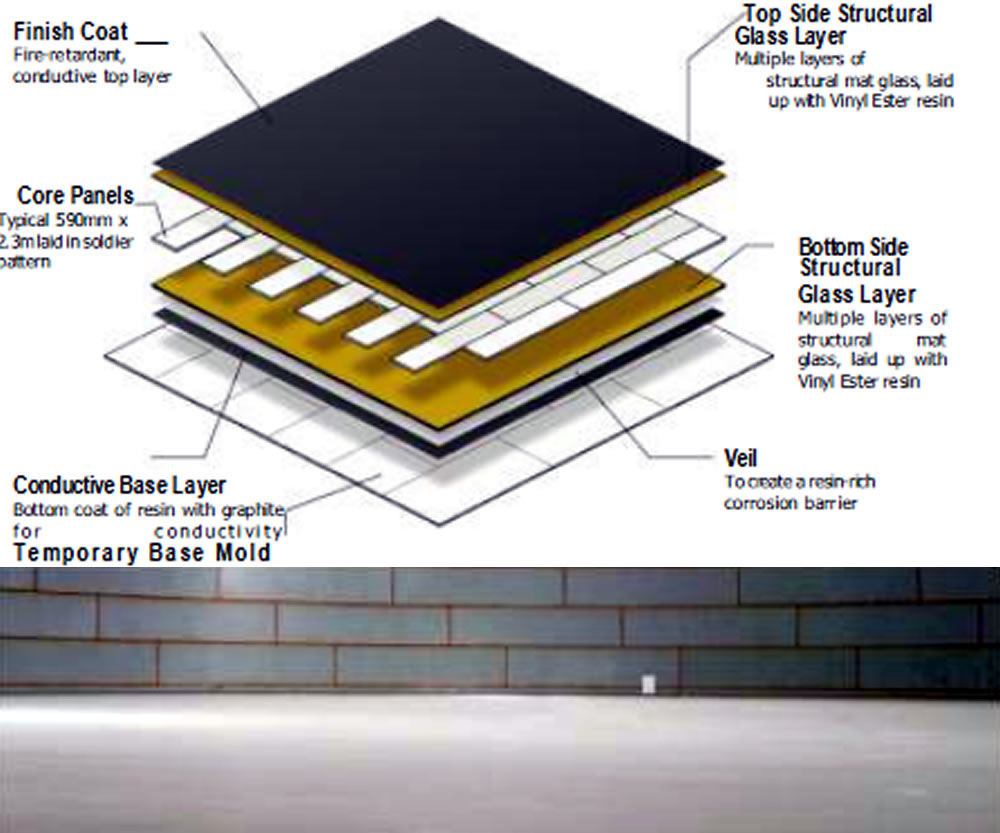

DECKMASTER ADVANCED COMPOSITE FLOATING ROOF

The DeckMaster advanced composite floating roof is a seamless, non-metallic full-contact floating roof. It’s gas-tight polypropylene honeycomb core is “sandwiched” between multiple layers of fiberglass utilizing modern high-grade Vinyl Ester resins designed to be resistant to most hydrocarbons in the petrochemical industry. The result is a smooth, seamless and virtually indestructible full-contact floating roof that also is corrosion free, thus necessitating little or no maintenance.

The DeckMaster remains in full contact with the stored product, preventing evaporative losses. The low-profile cross section of the roof maximizes the storage capacity of the tank.

Designed to accommodate both a mechanical shoe primary seal and a secondary seal, the DeckMaster is fully gas-tight, leak proof and unsinkable. The robust design also enables it to withstand operational stresses such as pigging and butter washing

Backflow protection and peace of mind —

the SumpMaster ® keeps your roof protected from product backflow in the event of drain system failure

Maintenance -free — corrosion resistant, stainless steel construction

Superior sealing capability — in the event of product backflow, the SumpMaster ® will seal more effectively than traditional systems. Over time, metallic -ball systems develop dents from normal movement, resulting in an uneven sealing surface. The non-metallic ball of the SumpMaster® will not wear or dent, maintaining excellent sealing capabilities for

the life of the tank

Fast and easy installation — easy bolt on/bolt off flanges

Custom designed — SumpMaster ® can be fit with the customer’s choice of flanges

• Full-contact design — to eliminate vapors below the internal floating roof

• Gas-tight design — to accommodate both a mechanical shoe primary & secondary seals

• High strength — to withstand pigging, light-end slugs and turbulence from high fill rates

• Seamless — single-piece construction qualifies for zero-deck-seam emissions per EPA air rules

• Chemically resistant — to all products typically stored in floating roof tanks

• Fire retardant — tested by certified third-party specialist (Last Fire Group) and approved for perimeter-only fire protection per NFPA 11, 2015 edition.

• Bolted Option — available in pre-fabricated bolt-up panels for specific applications.

• Smooth surface excel lent for cleaning

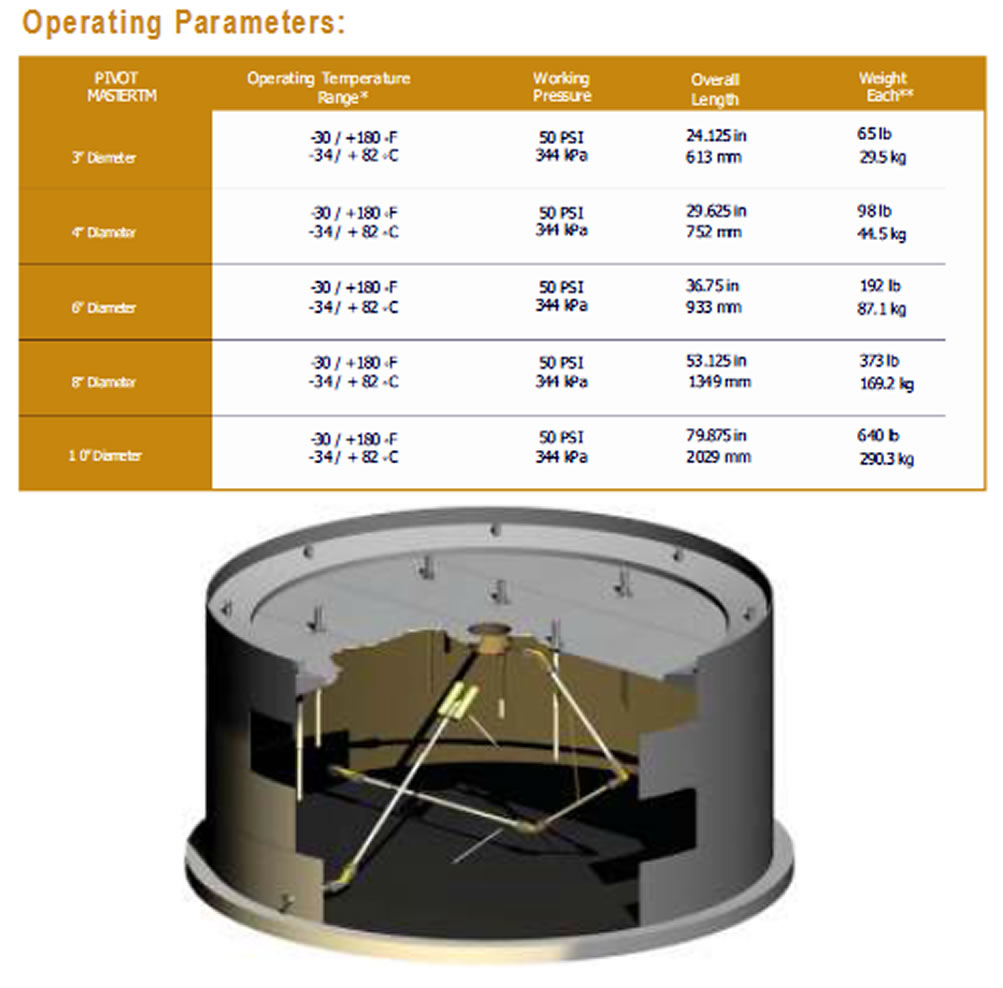

HMT PIVOT MASTERTM Flexible Joint

The HMT PIVOT MASTERTM Flexible Joint was designed to provide a superior solution to floating roof drainage over mechanical swivel joints and flexible hoses. The HMT PIVOT MASTERTM Flexible Joint consists of a specially designed composite type hose contain ing ANSI 150# raised faced flanges secured in place by a pivotal steel side plate structure.

The composite hose is designed with inner and outer stainless steel wire helixes and multiple inner layers of polar and non-polar elastomeric materials. The stain less steel wire helixes maintain the hose rigidity when subjected to internal or external pressures.

Utilizing various layers of Polar and Non-Polar elastomeric materials prevents permeation of products through the hose along with providing a 100% aromatic resistance. The composite hose is secured within two reinforced steel side plates (primed or galvanized carbon steel or stainless steel). These side plates are joined by a stainless steel pivotal pin that uses stainless steel bushings and spacers to eliminate binding and assure flexibility.

Applications of the PIVOT MASTERTM Flexible Joint include, but are not limited to, Floating Roof Drain Systems, Floating Suctions Systems and Floating Skimmer Systems.

HMT PIVOT MASTERTM Floating Suction & Skimmer Systems

HMT provides Floating Suction Systems designed to enable the removal of the stored product near the product surface, contaminate -free. HMT’ s Floating Suctions are engineered to operate in conjunction with all types of floating roofs or without a floating roof.

The HMT Floating Suction System is designed to meet all requirements of the storage tank size and submerged environment. All components are compatible with the stored product providing a long life and trouble free system that will be custom designed for your

specific application.

HMT Floating Suction units (3” – 10”) utilize

the HMT PIVOT MASTERTM Flex Joint instead of a mechanical swivel, rigid piping (carbon steel, stainless steel or aluminum) and custom designed pressure tested flotation chambers.

HMT PIVOT MASTERTM Floating Roof Drain System

The HMT PIVOT MASTERTM Floating Roof Drain System is designed to innovatively provide a better solution to floating roof drainage problems. Introduced in 1982, this system combines the flexibility of the v arious flexible hose / pipe systems with the strength found in rigid pipe / swivel joint systems. The PIVOT MASTERTM Drain System is a steel pipe drain system with flexible hose joints capable of withstanding an extremely wide range of service conditions.

The system effectively provides positive roof drainage with maintenance -free and worry -free operation. This results in extended service life, with no hose kinking or clogging and no stress loading on O -rings, bearings or seals. Instead of costly swivels, t he PIVOT MASTERTM employs unique flexible joints in a straight -line design, with no offsets to cause unbalanced loading.

The PIVOT MASTERTM is easily installed in a fixed position, requiring a minimal operating area. With a designed continuous slope, the P IVOT MASTERTM does not allow sediment to become trapped in the

system. It is designed for submerged service with no lubrication required and there are no corrosion freeze -ups. PIVOT MASTERTM components are compatible with 100% aromatic products and can withstand high design pressures.

Designs available:

Standard – For normal floating roof low leg heights Low Profile – Two designs for low heel tank designs Multiple – Two or more standard or

Low Profile drains per tank

PIVOT MASTERTM Drain Systems can be designed to avoid interferences with heating coils, diffusers and other internal obstructions. Stress and flow rate calculations are available upon request.

We Are Among the Best in The Industry

Are you looking forward to having an experience of our quality service?